|

| July 21, 2020 | Volume 16 Issue 27 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New nylon constant torque hinge

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Learn more.

What injection molding material do I use?

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

Read this detailed Xometry article.

What are carbon composite bellows springs?

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

Learn more.

Conductive Brush Ring overcomes current leakage in EV powertrains

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

Learn more.

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

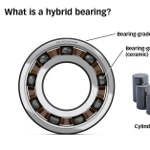

Why hybrid bearings are becoming the new industry standard

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

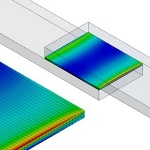

3M and Ansys train engineers on simulating adhesives

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

Satellite design applied to largest aluminum sailing superyacht ever

The superyacht Sea Eagle II. [Photo: © Royal Huisman]

Dutch shipbuilder Royal Huisman applied the same concurrent engineering process developed by the European Space Agency (ESA) for space missions to the design of superyacht Sea Eagle II, due to become the world's largest aluminum sailing yacht when delivered to its owner this spring.

This uniquely contemporary 81-m-long (266-ft) three-masted schooner was recently transported by barge from the company's shipyard in the Dutch city of Vollenhove to Royal Huisman Amsterdam, where its carbon composite rig will be installed, leaving her ready for sea trials and on-board crew training.

Sea Eagle II's modern style extends to its design, which took place using concurrent engineering, taking inspiration from the long-established Concurrent Design Facility (CDF) at ESA's technical center ESTEC in Noordwijk, the Netherlands, where it is employed for performing preliminary design and assessment of potential future space missions and systems.

"Satellites and superyachts are both complex machines, and concurrent engineering is advantageous in designing any complex system," says Massimo Bandecchi, founder of ESA's CDF. "The basic idea is simple: Bring together all necessary experts and design tools into a single room to work together as a team on a shared software model that updates immediately as changes are made, to assess design feasibility and tradeoffs in a much more effective and reliable way.

"While our main focus is fulfilling the needs of ESA engineering, there has also been strong interest in our work from industry. Concurrent engineering's improved performance in terms of time, cost, and efficiency speaks for itself. The result is that more than 50 centers have been built following ESA's original CDF model and are now in operation across Europe -- the majority in the space sector, plus around 10 non-space centers."

Stefan Coronel, Royal Huisman's design and engineering manager, received training from Bandecchi and his team before setting up his own concurrent engineering room. "Yacht building is not rocket science," he says, "but it does involve a complex, multi-disciplinary system, with lots of tradeoffs to be decided."

"The traditional 'over the hedge' design method -- where one knowledge field does its work, then throws it across to the next team in sequence -- demands the subsequent checking of feedback then possible design adjustments, so is quite a time-consuming process. In the modern yard-building world, there isn't so much time to spare.

"That said, compared to the dramatic shortening of satellite conceptual design time achieved by ESA, the main benefit we see from concurrent engineering is not gaining time but that the quality of the final design ends up much better, and more complete -- giving us confidence to proceed to the build phase."

Royal Huisman is now applying concurrent engineering to all of their new builds, and many of their refitting and service projects.

"Our room is not as fancy as ESA's CDF, but has the same basic approach of a place where everyone can contribute," says Coronel, "with means of accessing all normal engineering tools and calculation methods, plus a splinter room for small separate discussions."

In the same way that satellite design is broken down into subsystems, yacht design involves some main disciplines taking part in all the sessions: structural strength and stiffness; deck and sail handling; systems such as propulsion, power, heating, and air conditioning; electronics; and finally interior design -- creating a desirable, luxurious interior. Additional external experts, such as noise and vibration specialists, attend as required.

"The kind of tradeoffs that concurrent engineering makes easier to resolve include such deceptively simple tasks as placing a side hatch or staircase," says Coronel. "In the case of a hatch, it would need to be watertight and endure loads from sea waves, while also integrated with the living space and looking good when trimmed with wood. Any staircase needs to be open and attractive, while also having pipes and electrical cables run through it, and meeting all relevant fire and safety regulations."

The company's adoption of concurrent engineering also meant Sea Eagle II's aluminum panels have had holes and support structures added to them in advance, saving time in construction and the integration of features such as winches or hatches.

European companies and institutions have variously adopted concurrent engineering for educating students, designing automobiles, planning oil platforms, and optimizing the production plant of dairy product company FrieslandCampina.

Source: This article was reposted with permission from the European Space Agency (ESA). Read about more ESA developments at www.esa.int.

Published March 2020

Rate this article

View our terms of use and privacy policy